What is 48V/Mild Hybrid drive technology?

Lower fuel consumption and emissions with easy implementation in existing vehicle platforms: That's what makes 48V mild hybrids so interesting in the transition phase to e-mobility. On this page, you can learn all about this technology, which is currently spreading across a wide range of manufacturers and vehicle classes.

Mild hybridization: Overview of functions, benefits and fields of

Mild hybridization - A brief overview: What makes a car a mild hybrid?

What makes a car a mild hybrid, and what does 48V stand for?

Why do we need mild hybrids at all?

What are the benefits for the driver?

How does mechanical integration in the powertrain work?

For which types of vehicles can 48V be used?

What makes mild hybridization interesting for manufacturers as well?

What 48V solutions does SEG Automotive offer?

What career opportunities are there in SEG Automotive's 48V Division?

Mild hybridization - A brief overview: What makes a car a mild

Mild hybrids make conventional combustion engines significantly more efficient with little effort. This involves recovering kinetic energy while the vehicle is braking (" recuperation") – just like the Energy Recovery System (ERS) in Formula 1.

This energy, otherwise lost, is stored in a 48V battery and then used to support the engine and power a high-performance 48V on-board electrical system. In addition to other benefits, this mild hybridization cuts fuel consumption by 15% or more – and thus reduces CO2 emissions accordingly.

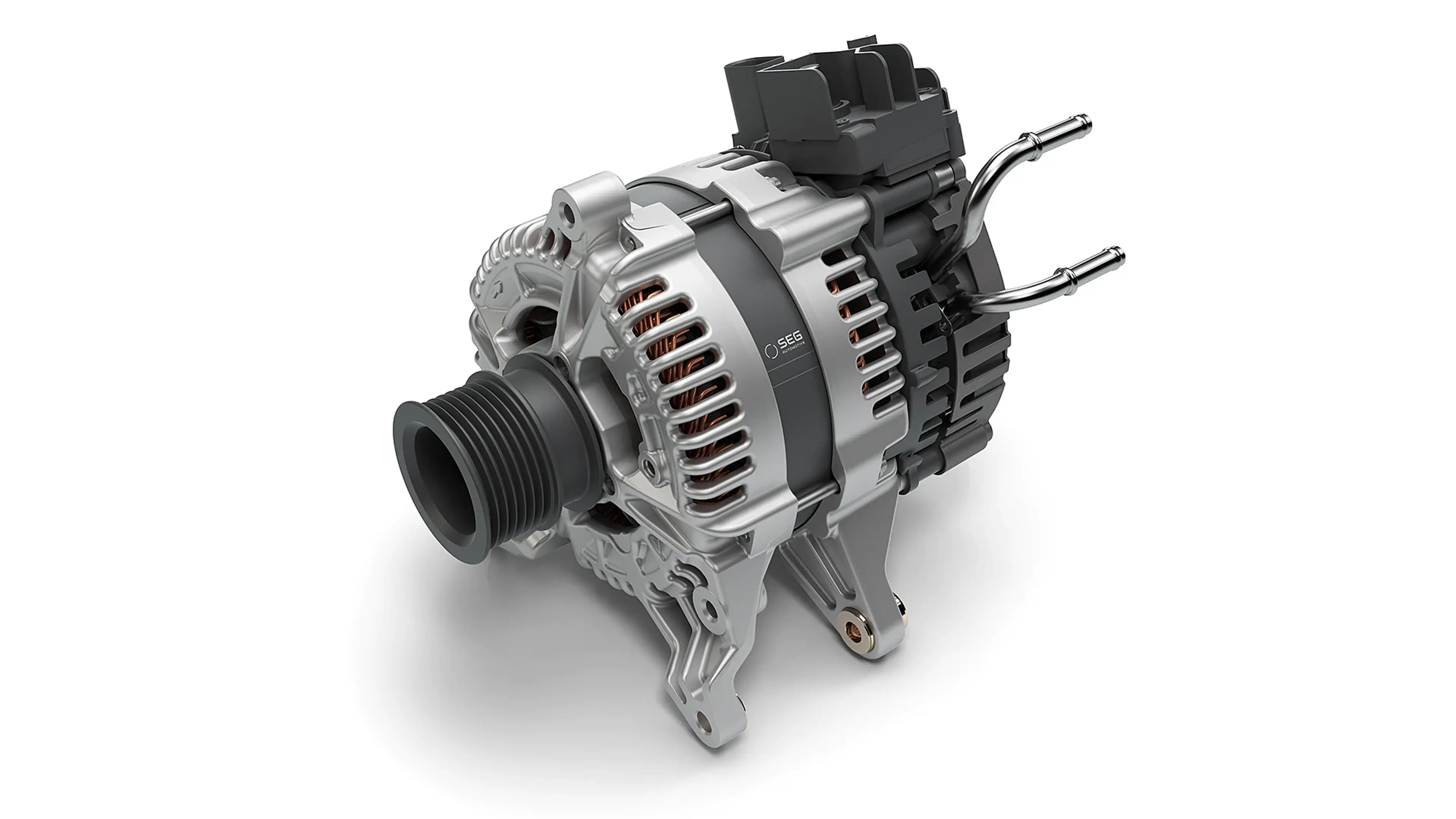

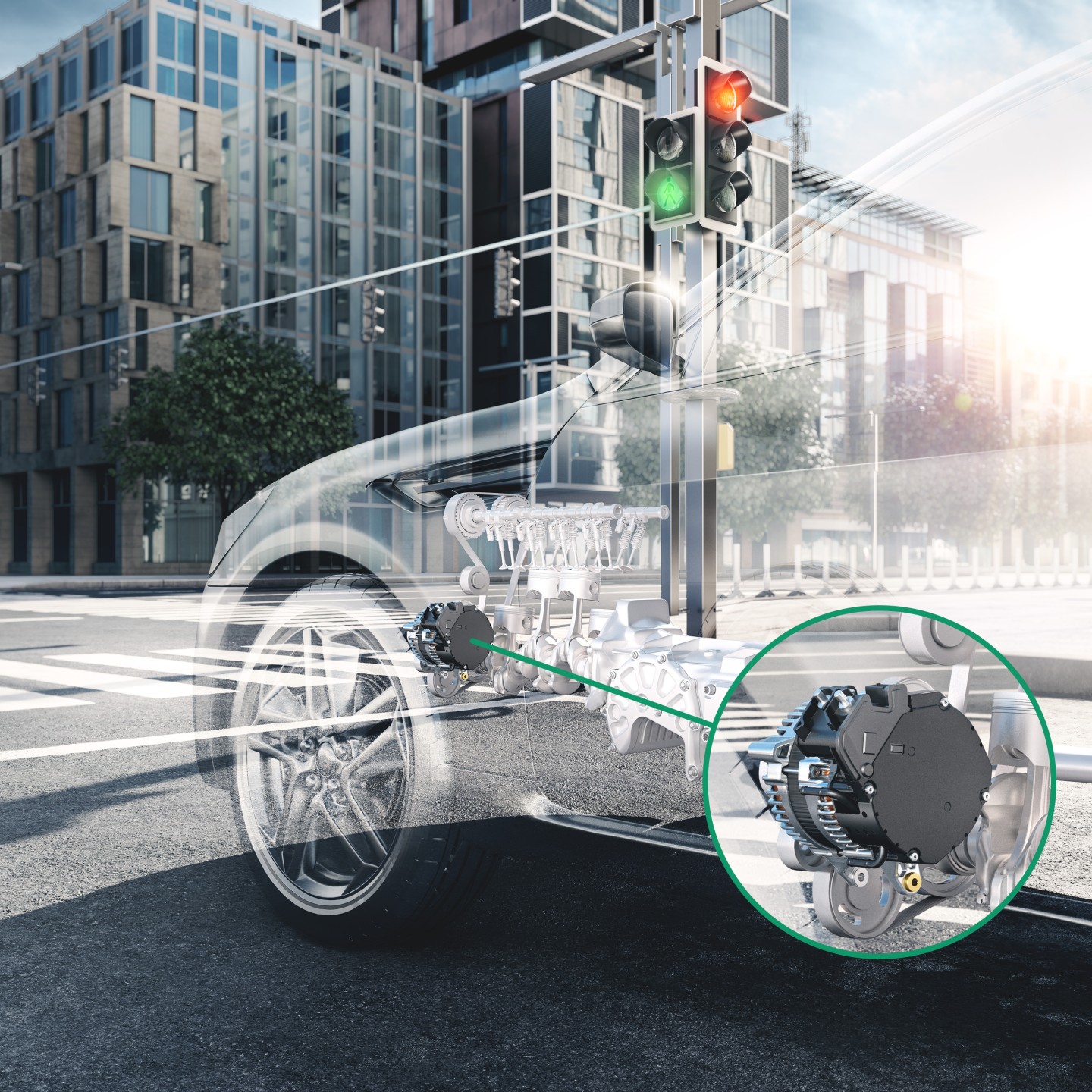

In the simplest implementation (" P0 topology"), the conventional 12V generator is replaced in its integration space on the belt by a 48V machine – a Boost Recuperation Machine, for example. It converts kinetic energy into electrical energy with high efficiency during braking and stores it in a small, additional 48V battery. It also supports the combustion engine with up to 12 kW of electrical power. In addition, safety-relevant high-performance consumers such as driver assistance functions or electric brake boosters can be reliably supplied with 48V voltage.

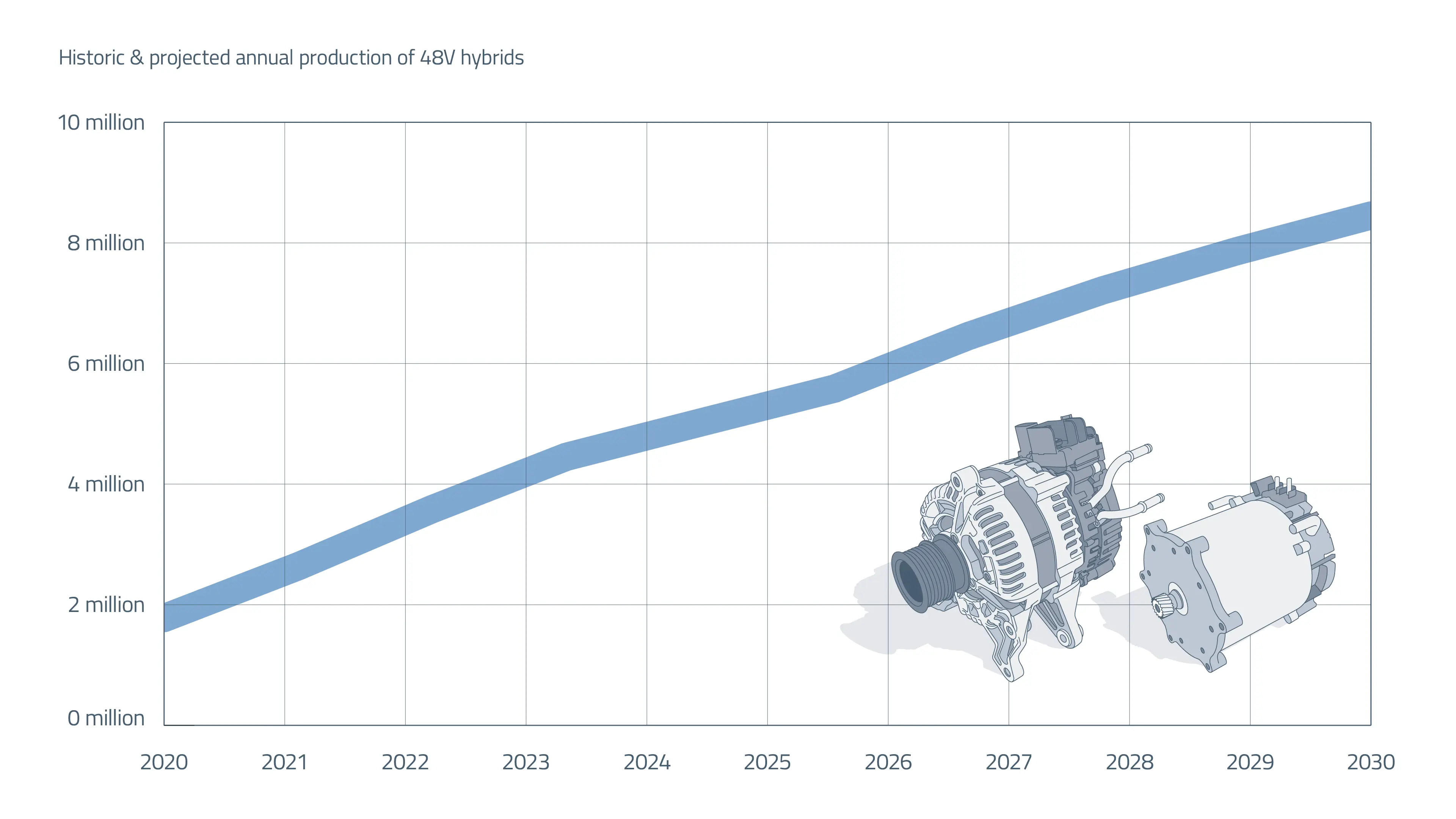

A 48V machine can also be flexibly implemented at other positions in the powertrain – with varying degrees of integration effort and savings potential. To achieve the varying climate objectives in each region, mild hybrids are a vital component for automobile manufacturers. The technology is showing up in an increasing number of models and vehicle classes. Over 4,5 million vehicles have been equipped with a 48V machine already, primarily with P0 topology. Market research company [Opens in a new tab] IHS Markit expects global annual production of 48V mild hybrids to be well over 10 Million as early as 2025.

What makes a car a mild hybrid, and what does 48V stand

A mild hybrid refers to a vehicle with an internal combustion engine that is also supported by a small electric drive. The electric motor recovers braking energy ("recuperation") and makes it available later as additional drive power to reduce overall fuel consumption. In contrast to a full hybrid or an electric car, a mild hybrid can be driven in purely electric mode only to a limited extent.

There are also some mild hybrids operating on 12V. In most cases, therefore, a more powerful 48V machine is used, which recuperates more energy and thus also reduces fuel consumption to a greater extent. Experts, therefore, often use the terms "mild hybrid" and "48V" interchangeably.

Why do we need mild hybrids at

This technology offers many benefits for drivers and manufacturers - at low implementation costs.

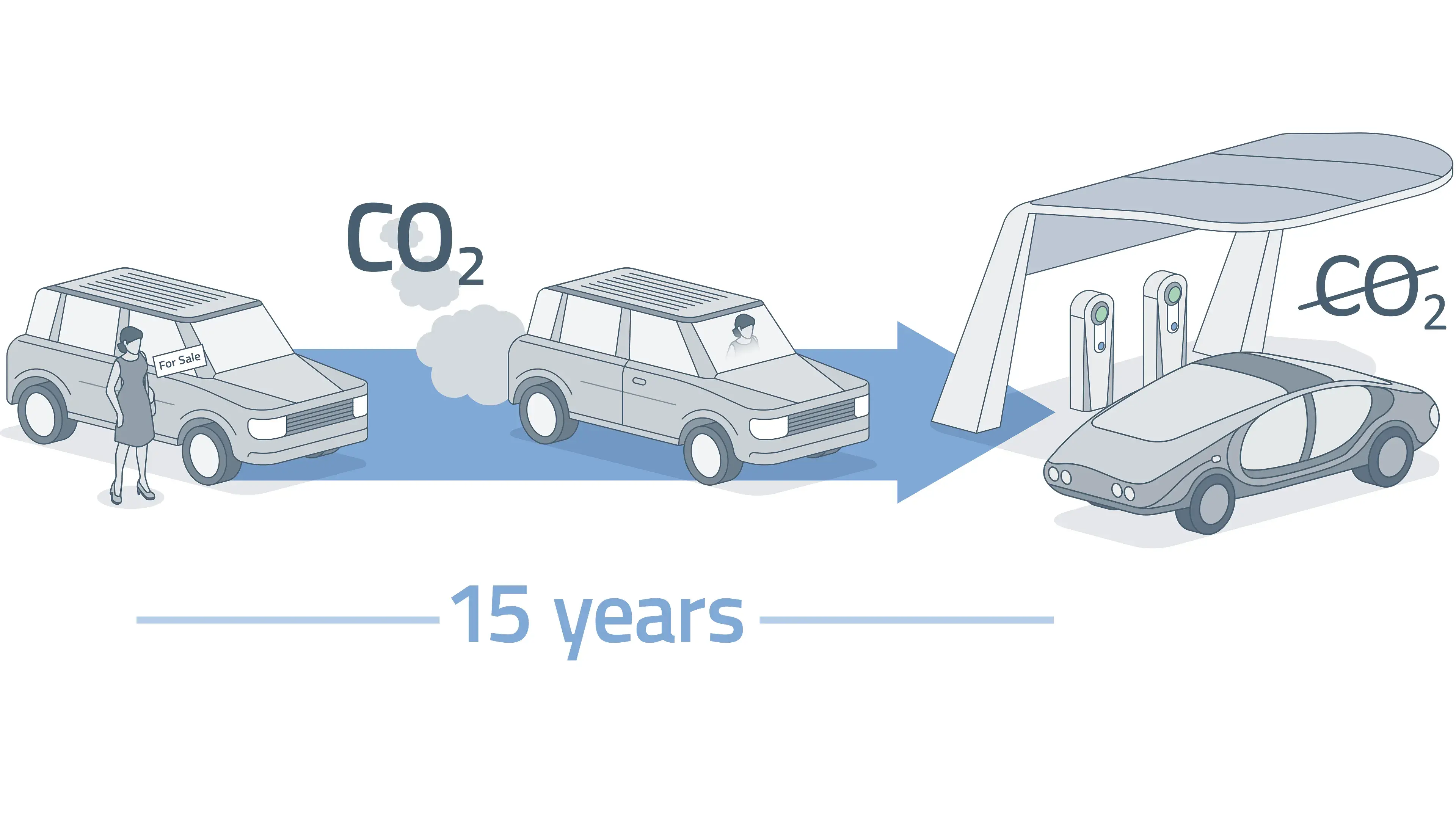

The most important factor is climate protection, though: e-mobility is emerging, primarily due to the unequivocal political commitment in core markets such as Europe and China. However, this

transformation cannot be accelerated at will after all, technology, battery availability, infrastructure, and power generation must be further developed simultaneously.

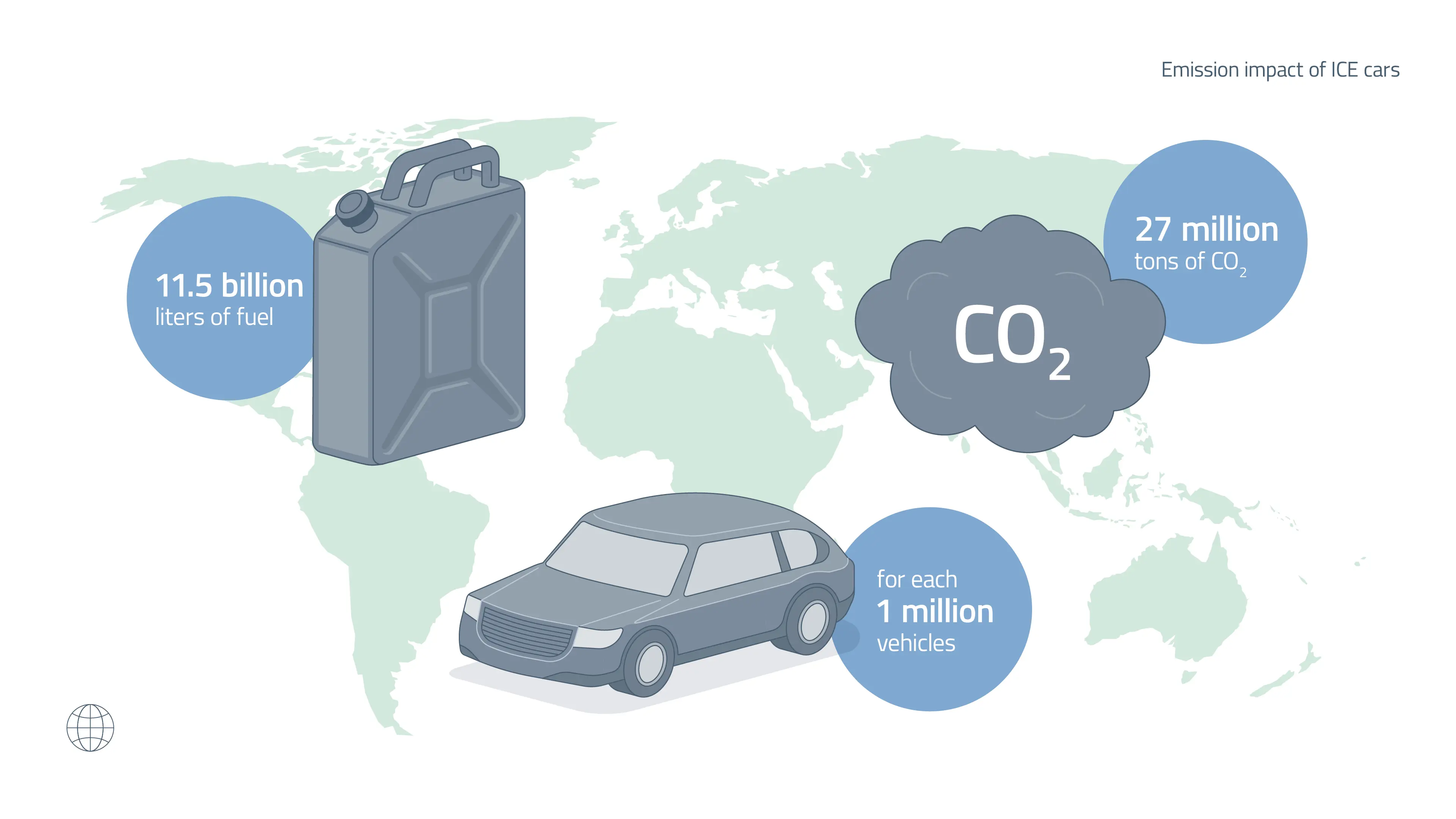

According to multiple studies, hundreds of millions of additional cars with an internal combustion engine (ICE) are still going to be built in the next two decades. This is partly due to the much slower shift to e-mobility in regions such as Africa, Latin America and India.

These future ICE cars would cause billions of additional tons of CO2 emissions, which we cannot afford to meet the 1.5-degree or, at the very least, the 2-degree target.

These vehicles must be designed to be as efficient as possible to minimize global climate change. Mild hybridization can prevent 15%-25% of these emissions. Neglecting this technology would mean losing this savings potential forever.

Equipping all one billion combustion vehicles to be produced by 2040 with 48V hybridization would save at least two billion metric tons of CO2 – around three times Germany's total greenhouse gas emissions in 2020. With more complex topologies, savings of 4 billion metric tons and more are possible through 48V hybridization.

What are the benefits for the

"Upgrading" from a conventional combustion engine to a 48V mild hybrid earns the driver a significant increase in the performance range. For example, with a 48V Boost Recuperation Machine braking energy is recovered while driving with up to 15 kW / 20hp to then support the engine with up to 12 kW/ 16 hp when power requirements increase (Boost). It can also eliminate the turbo lag at low engine speeds.

The vehicle can start particularly smoothly and quietly thanks to the 48V engine, and high-consumption comfort. "Coasting" - i.e. driving with the engine switched off at high speeds - becomes possible and can save additional fuel.

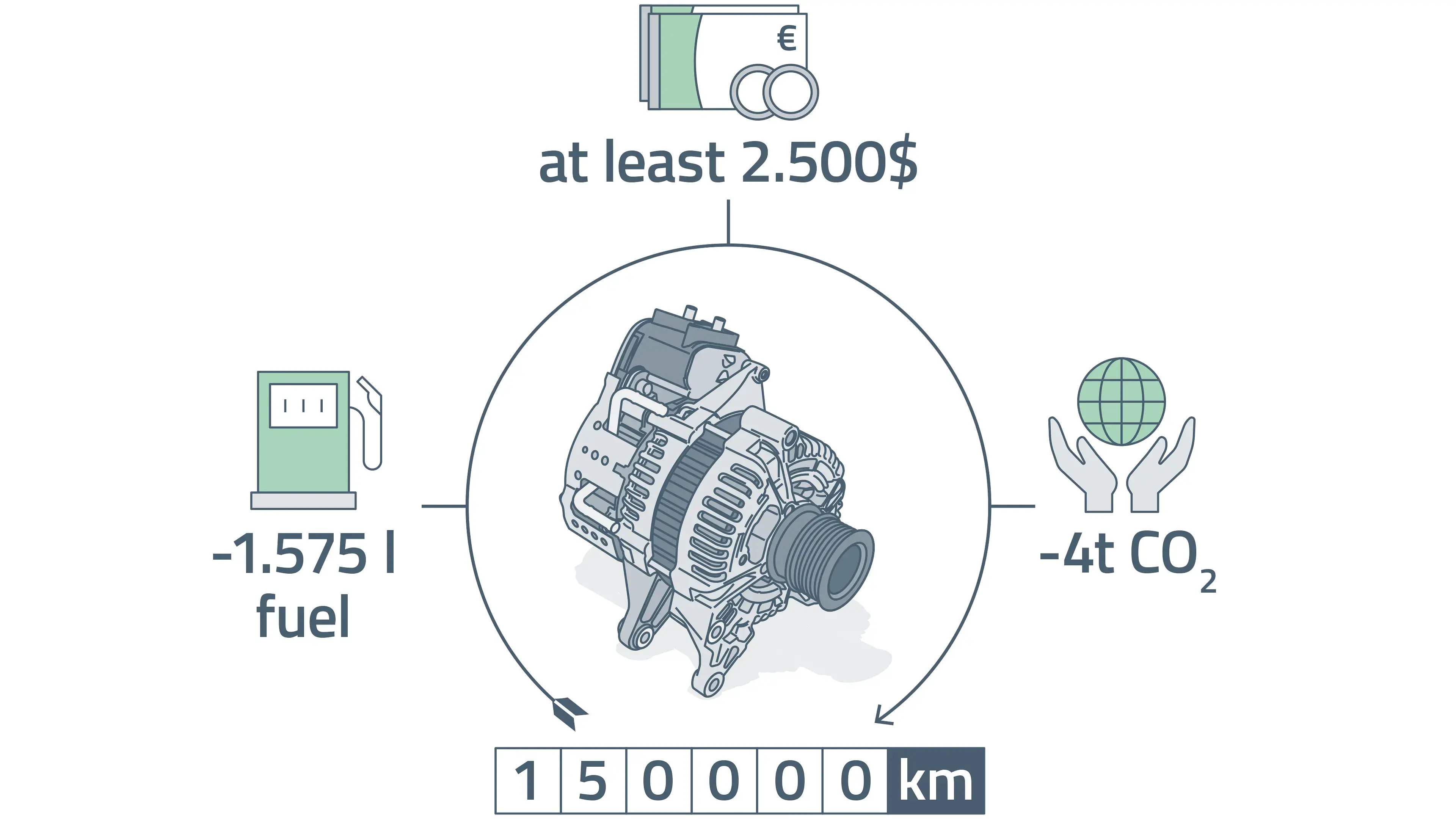

Thanks to significantly reduced consumption, mild hybrids are a better solution not just for the environment, but also for the driver’s budget: Over a lifetime of 150,000 km, for example, the 48V

Boost Recuperation Machine saves over 1,500 liters of fuel compared with a conventional combustion engine. This translates into around 4 tons less CO2 emissions and at least € 2,000 less spent at the gas station.

An electric car is not an option for everyone today. Reasons for this could be a lot of long-distance driving or the lack of a sufficient local charging infrastructure. In this case, 48V hybrids are a practical solution that minimizes the climate burden and makes driving yet more comfortable and safe.

How does mechanical integration in the powertrain

Mild hybrid technology can be integrated into all existing powertrain architectures for internal combustion engines. Depending on the desired level of performance and CO2 savings, the effort ranges from very low to medium.

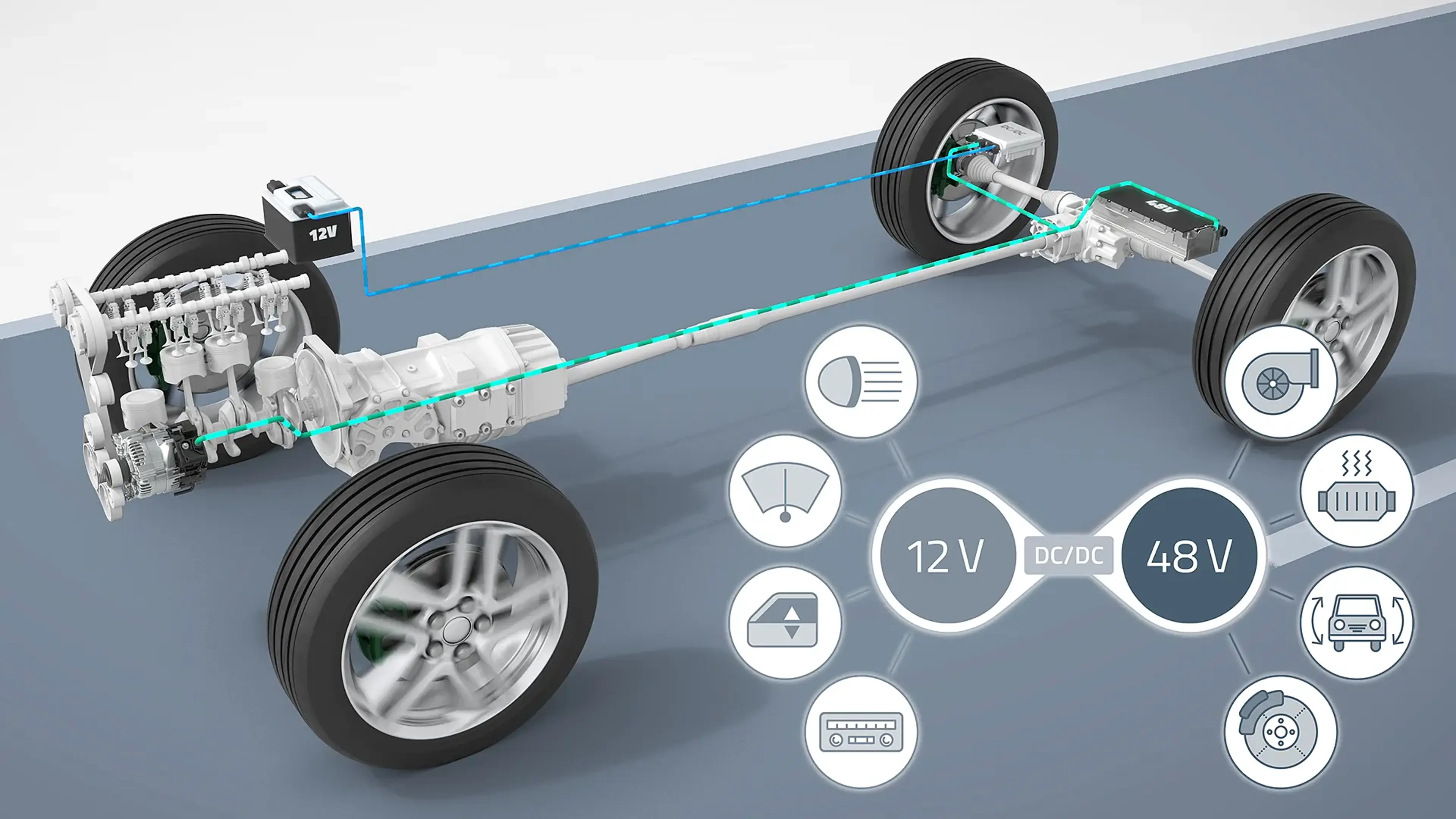

Mild hybridization always requires installing an e-machine with an inverter in the powertrain in addition to the combustion engine. On top of that, a small 48V battery (~0.5 - 1kWh) is added to feed the 48V on-board electrical system. Lastly, a DC/DC converter supplies the 12V on-board electrical system. On the other hand, the lower voltage makes complex and therefore expensive high-voltage protection requirements and cable harnesses unnecessary.

The required e-machine can be flexibly installed in the powertrain – on the belt, in the transmission environment, or on the rear axle. The CO2 savings, e-driving capabilities, the integration effort, and the associated system costs all depend on where the 48V machine’s position in the powertrain. This placement is also called "topology", with the installation positions being abbreviated as "P0" to "P4".

P0: belt integration

is the most basic solution for mild hybridization. For this, a 48V machine such as the BRM simply replaces the generator in its existing integration space on the belt. Modification of the powertrain architecture is minimal – and so are implementation efforts and system costs. Nevertheless, the recuperation of this "

starter generator" can already reduce fuel consumption by up to 15% in real-world operation compared to a conventional combustion engine.

P1: between the combustion engine and the transmission

However, this is rarely used in practice, as implementation here is more complex and costly than with P0, without leveraging further savings potential to a great extent.

P2 / P3: transmission setting

P2 indicates an integration directly on the side of the main transmission or connected via a belt, P3 describes the position directly behind it on the drive shaft. Both topologies feature a comparable cost/benefit ratio. However, they are mechanically much more complex than P0. For example, the e-motor needs to be installed in the transmission not as a whole but as individual components, and air cooling is not possible. In addition, a starter motor is usually still needed in this setup, which also drives up costs.

In return, higher savings of up to 22% can be realized due to lower frictional losses in the engine. Slow, purely electric driving ("creep/crawl mode"), e.g. when parking or during stop-and-go in traffic jams, is technically possible as well.

P4: rear axle

Integration of one or two 48V machines on the rear axle via a differential gear. Frictional losses in the powertrain are lowest here, allowing for the highest savings (up to 25%). In addition, this topology offers the most comprehensive e-driving functions. Besides the "creep/crawl mode", a (temporary) all-wheel drive could be enabled in conjunction with the combustion engine. This solution represents the most extensive modification of the powertrain and entails the highest system costs. In this case, an additional starter or starter-generator is also still necessary.

On the other hand, with the appropriate transmission ratio and power of the e-motor, P4 topology can also be used to drive 48V full hybrids or even compact 48V electric vehicles - without the safety architecture otherwise required for high-voltage.

What is the benefit of the 48V on-board electrical system? Does it replace the 12V on-board electrical

The number of electrical consumers in cars today is much higher than it used to be. Safety and comfort features such as active wheel suspension or windshield heaters are just as energy-hungry as high-performance pumps or turbochargers.

Due to the four times higher voltage level, a 48V machine can recuperate and significantly more kinetic energy. It then reliably supplies high-performance consumers and enables additional driving functions such as comfort start, boost and coasting. At the same time, 48V is a low enough to be non-hazardous to humans. In contrast to high-voltage systems, the 48V on-board electrical system therefore has no special safety requirements.

A 48V mild hybrid actually has two electrical systems. The conventional 12V system continues to supply all low-voltage consumers, such as the radio, headlights, or window regulators. Not switching these components to a different voltage level results in less complexity associated with system integration. A DC/DC converter connects the two electrical systems – the recuperated braking energy can therefore also supply the 12V electrical system.

Comparison of technologies: What is the difference between a mild hybrid, full hybrid, plug-in hybrid and an electric

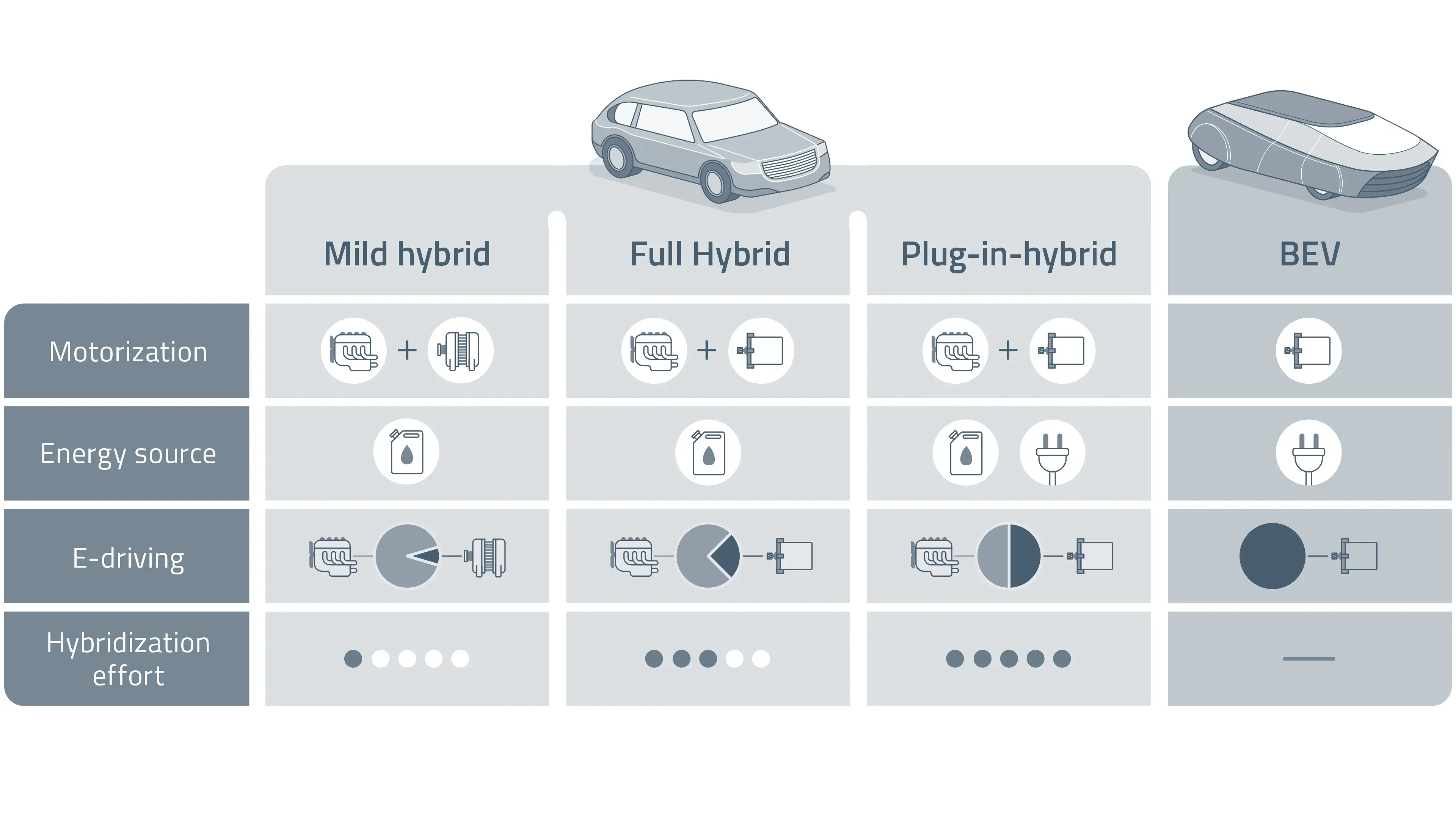

All these drive concepts have an e-motor on board - but they differ especially in terms of primary energy source, voltage level, and electric driving functions.

Mild-Hybrid

With mild hybrids, the main drive is the combustion engine. The e-machine primarily serves to improve efficiency: Braking energy is recovered, stored in a small 48V battery (~0.5 - 1 kWh), and used for additional torque and to supply the on-board electrical system. This saves 15-25% of fuel consumption, depending on the topology. Purely electric driving is not possible at all or only with severe restrictions.

Plug-in-Hybrid

A plug-in hybrid has two full-fledged drives – an internal combustion engine and a high-voltage electric motor. This "double motorization" and the larger battery (often around 10-20 kWh) add costs and weight. In return, purely electric driving is usually possible for around 40-80 km, and the combustion engine is theoretically only necessary for cross-country travel. The battery is charged via a socket, such as the household mains.

Full-Hybrid

The full hybrid is based on the same principle as a mild hybrid. Energy is only supplied to the system externally via fuel, while the e-motor recuperates kinetic energy during braking and makes it available again later. The difference: Full hybrids usually operate on a high-voltage basis and have a larger battery (usually 1,3 - 2 kWh). Security requirements and system costs are therefore significantly higher. On the plus side, even more energy can be recovered and stored, and short distances can be driven purely with the e-motor.

E-Auto (BEV)

The battery-powered electric vehicle (BEV) does not need an internal combustion engine at all. It does, however, require significantly larger batteries – around 10-20 kWh of battery capacity per 100km, depending on the model. Here, too, charging takes place via the home power socket – or at the growing network of public charging stations

There is currently no single best choice for every consumer – the differences are too significant in terms of personal needs (e.g., pure city car vs. professional driver) and regional requirements (especially with regard to the charging infrastructure and the share of renewable energy in the electricity mix). In the long term, the transformation of individual mobility is clearly moving toward BEVs; however, mild hybrid vehicles in particular can still prevent a lot of unnecessary CO2 emissions on this journey.

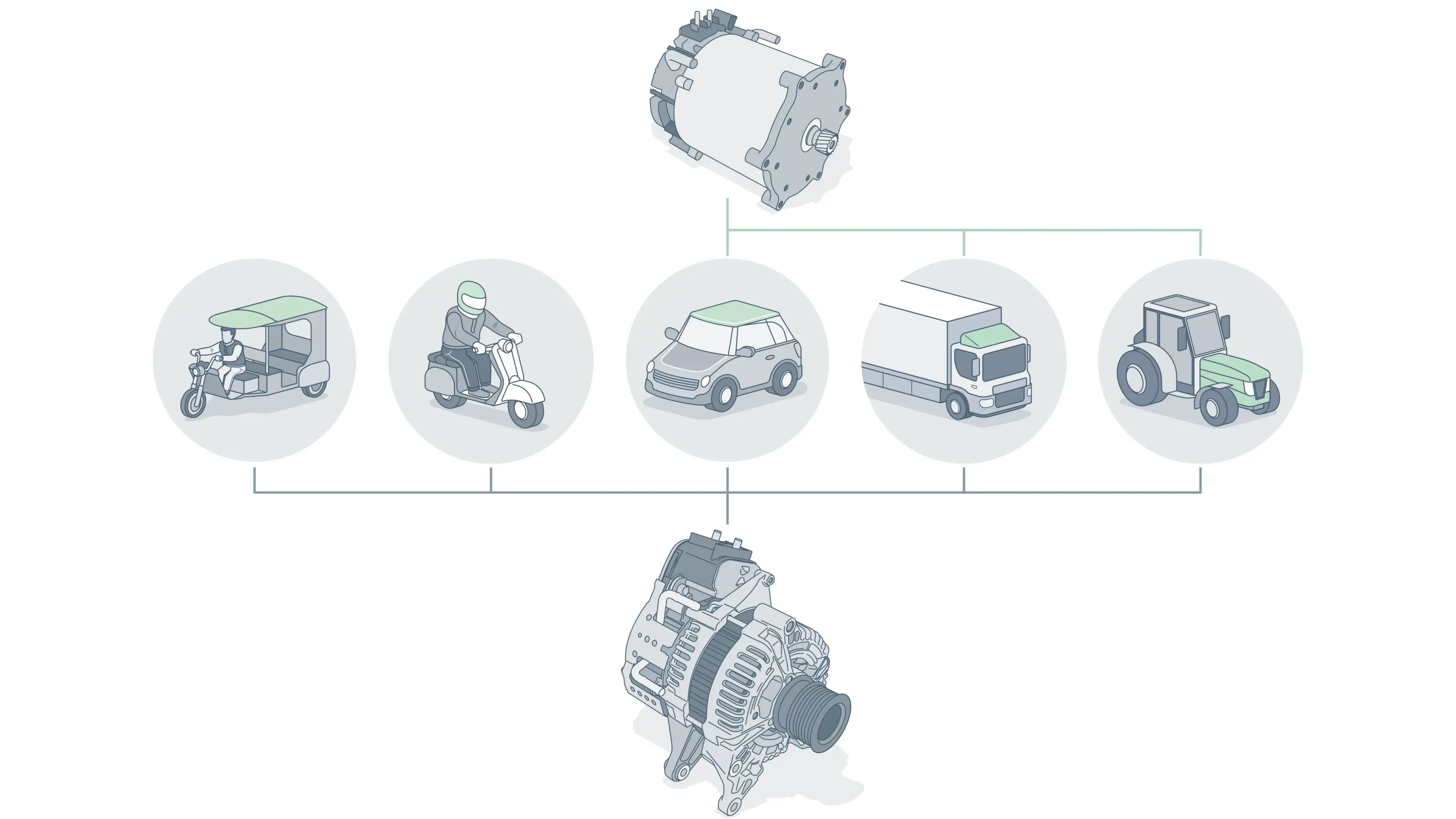

For which types of vehicles can 48V be

Combining a powerful e-motor with low safety requirements makes 48V machines suitable for a wide range of applications beyond mild hybrid applications.

In addition to the product portfolios of automobile manufacturers, 48V machines increasingly establish themselves as the main drive for light electric vehicles. These applications range from e-scooters like the Schwalbe to electric rickshaws and minivans in India.

In passenger cars, too, 48V can do more than just mild hybridization. E-machines can be scaled accordingly to deliver sufficient power to drive 48V full hybrids or even compact 48V electric vehicles. For example, putting two 48V e-Machines on the rear axle could accomplish this.

In the commercial vehicle sector, 48V machines are also opening up new possibilities – from the start-stop function in light trucks to the mild hybridization of heavy trucks. 48V systems also create new benefits and opportunities to reduce emissions in various off-road applications such as riding mowers.

Two and three-wheelers can be fully electrified with a 48V BRM, for example.

What makes mild hybridization interesting for manufacturers as

48V integrates three aspects that are very attractive for automobile manufacturers, especially in combination: Significant reduction of CO2 emissions, marketable benefits for the end consumer, and cost-effective integration into existing vehicle platforms.

Increasingly stringent CO2 limits are putting pressure on manufacturers to make their vehicles ever more efficient. The systematic introduction of 48V hybrids across the portfolio can reduce fleet consumption quickly and effectively. It also makes it easier to meet emissions standards such as Euro7 in the future – on the one hand due to lower fuel consumption, but also because the 48V on-board electric system can preheat the catalytic converter during cold starts, and thus reduce emission spikes.

At the same time, with its benefits for the driver, 48V has become and additional purchase incentive. Customers are wooed explicitly with the lower consumption and additional features such as comfort start or boost.

The mechanical integration effort is very manageable. A 48V machine can easily replace the conventional generator in its installation place on the belt with a low cost impact in virtually all existing vehicle platforms. The 48V hybrid system is not only economical for the customer – it can also save costs for the manufacturer by avoiding possible penalty payments. In the EU, for example, an easy-to-achieve saving of 10g CO2 per km through mild hybridization would correspond to an avoided penalty payment of € 950 – essentially – essentially covering the system costs for a P0 solution.

What 48V solutions does SEG Automotive

SEG Automotive develops products for all powertrain architectures – regardless of whether the energy comes from fuel, battery, or hydrogen. Our goal is always the same: to make the vehicle as efficient as possible. Our robust solutions thus accelerate the shift to more efficient combustion engines, electric vehicles and climate-neutral mobility.

Specifically for 48V, we offer three product families for a variety of applications. Beyond hardware, we provide complete system solutions with power electronics, controllers, and software calibration to ensure seamless integration and optimized energy management. Whether it is a full system or individual components, we give our customers flexibility for cost-sensitive platforms and premium applications alike.

What career opportunities are there in SEG Automotive's

The complexity of cars has increased rapidly in recent years, and not just because of autonomous driving functions. As a result, our 48V and electrification products are backed by closely integrated teams for hardware, software, electronics, testing and manufacturing. From validation, prototyping and process development to coding and quality assurance, we offer exciting job profiles for engineers, software developers, logistics specialists, and more. See our Job Portal for more information.